Facility and Equipment

Three of our painters in our fine paint shop putting on an color undercoat on a large plaque

CNC ROUTERS, WOOD SHOP, METAL SHOP & PAINT SHOP

Most of our operations and personnel are located on a 14,000 ft2 factory in two industrial buildings in Murrieta, CA, at 41785 Elm Street, Suite 302, in the Temecula Valley located in Riverside County in Southern California. The Temecula Valley is well-known for its over fifty boutique wineries and vineyards. Our factory is located 60 miles north of San Diego, and about 90 miles southeast of downtown Los Angeles. We are surrounded by beautiful mountains, the highest being Mt. Jacinto, 10,834 ft, snow-capped in winter. Our customer relations staff, project coordinators, computer design facility and manufacturing factory are located at our Murrieta facility. We design and fabricate over 7000 signs and plaques each year in this facility. All of our products and nearly all their raw materials are "Made in the USA".

In our factory we have extensive computer design facilities, a fully-equipped Computer-Numerically-Controlled (CNC) Router Shop, a Wood Shop, a Metal Shop, a Paint Shop, and a Packing & Shipping area described below.

VIDEO. The short 1 minute U-tube video below (with sound) gives a brief overview of our manufacturing process.

Video of our Design and Manufacturing Operations

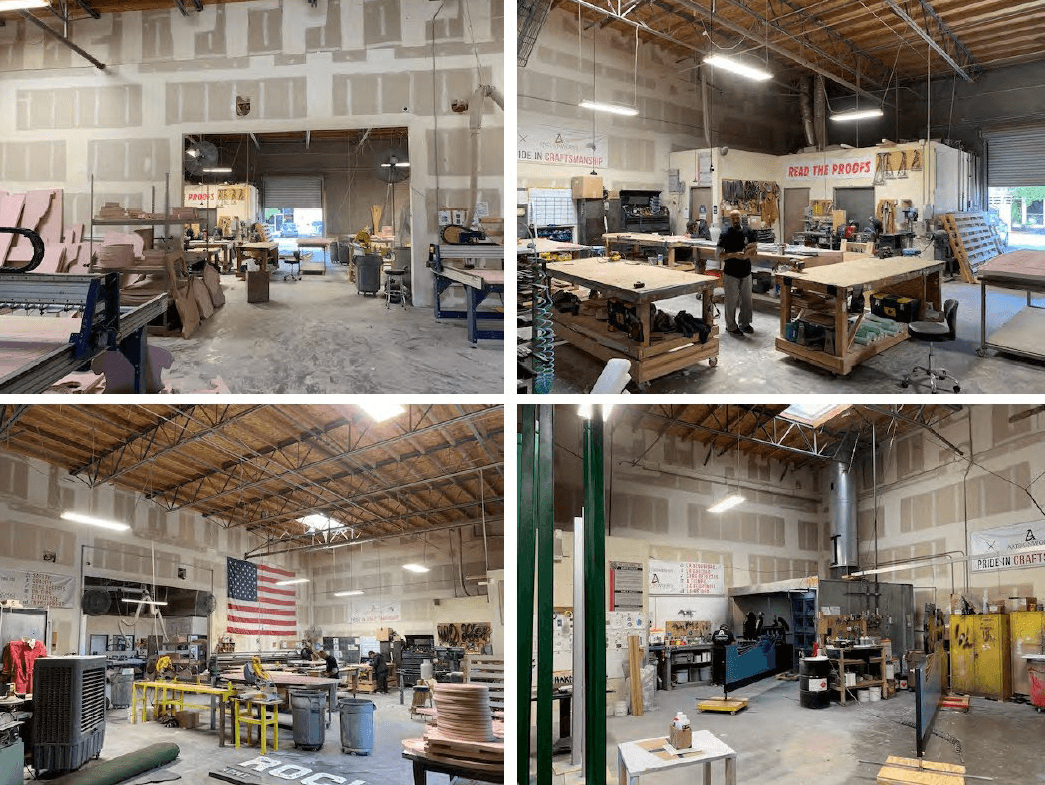

Fig. 2 - The top two and bottom left photos show our sandblasting, wood, and metal shops. The bottom right photo shows our paint spray shop.

CNC ROUTER SHOP. We use computers extensively to design our plaques and control the machines that perform the initial carving of our plaques. In our CNC Router Shop, we have seven large table routing/carving machines:

1. 12 x 5 ft table with Automatic Tool Changer, for 3-D, 2.5-D, and engraved carving of large signs

2. 10 x 5 ft table with Automatic Tool Changer, for 3-D, 2.5-D, and engraved carving of large signs

3. 8 x 5 ft table for 3-D, 2.5-D, and engraved carving of medium and small signs

4-7 . Four (4) 4 x 4 ft tables for 3-D carving of plaques and small signs

These are full-capability computer driven machines that are capable of automatically and precisely carving both 3-D and 2.5-D designs in High-Density-Urethane (HDU) and all species of wood. They can also cut out and engrave plastics such as PVC, HDPE, Acrylic, MDO, and thin sheet aluminum. To run these machines, we develop 3-D and 2.5-D geometric models of the plaque or sign to be carved using our design software ASPIRE, which is hosted on six computers in our facility and in three remote locations where our contract 3-D designers are located. These models are input into the computers which control our 3-D routers, where they are converted into tool paths used to guide the high-speed rotating router bits as they carve the plaques. These are precision machines with accuracies of 0.01 inches in all three dimensions. It takes from 1 hour to as much as 36 hours to carve one plaque on one of these amazing machines, depending on the size and intricate details of the plaque. 3-D plaques take much longer to carve than 2.5-D plaques. We also store large number of sheets of wood, HDU and other substrate materials waiting to be put on the router tables, as well as storing the carved plaques when they come off the tables.

Fig. 1 - The left photo shows two of our 6 CNC routers. Our sandblast booth is shown in the middle photo. A 2.5-D carved HDU sign after carving and sandblasting has been completed (before primer coating and painting) is shown in the right photo.

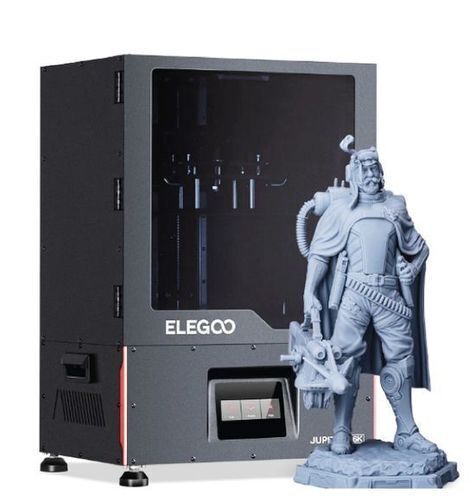

Fig. 3 -Shown is one of our 3D printers and a 3-D sculpture it made. . This printer can make 3-D bas relief, 3-D 50% relief with undercuts, and 3-D full relief sculptures similar to that shown. Sizes can range from 10" x 6" wide at the base and 11" high.

>

3-D PRINTERS. We have three ELEGOO 3-D printers that we use to make very precise 3-D smaller plaques, up to 10 inches in size and 0.1 inch up to several inches thick. These can make 3-D bas-relief, half-relief and even full relief (stand-alone 3-D) art pieces and appliques for larger signs and plaques. We can make small 3-D models of objects like ship anchors, cannons, ships, boats, autos, animals, people, etc and mount them on our HDU or wood plaques and signs. The photo on the right shows a typical 3-D printed object, a Viking Warrior. Note the detail. These printed 3-D art pieces are made of strong, tough photopolymer resin filament and can be painted in sign enamel colors or metal plated in bronze, brass, aluminum or copper.

We also store large number of sheets of wood, HDU and other substrate materials waiting to be put on the router tables, as well as storing the carved plaques when they come off the tables. Fig 1 below shows photos taken in our CNC Router and Wood Shops.

>

WOOD AND METAL SHOPS. . These shops are next door to our CNC Router Shop. We have a large sandblast booth (handles up to 14 feet signs), and a complete woodworking shop with many saws, routers, sanders, planers, joiners, drills, lathes, and 5 fine sanding and polishing tables. We have a complete dust collection system that reduces the wood and HDU dust from cutting, carving, sanding and drilling operations.We also have a metal shop where we can cut, bend, and weld various metals, and make custom aluminum signs, wrought iron hangers and scroll brackets, and steel and aluminum posts and frames and other metal structures. We have access to a CNC water-jet cutter that can cut elaborate metal shapes precisely. In our Metal shop, we also have a metal-plating and polishing facility (bronze, brass, copper, silver-nickel, aluminum and stainless steel). Fig 3 below shows a panorama view of our Wood Shop.

Fig. 3 - This is a view of part of our Wood Shop. Our sandblast booth (rear center), dust collection equipment (left), saws, drills, planers, lathes, trimming, hand-sanding equipment & tables, and three craftsmen are shown in this photo. Our six large table routers are in the adjacent bay through the large open arch , not seen in this photo.

PAINT SHOP. We have a full-capability Paint Shop, separated from the Wood Shop, to eliminate any dust problems. Figs. 4 and 5 below show views of our Paint Shop and packing & shipping area. We have a 16 ft wide paint spray booth, a large number of Matthews MAP and 1-Shot paint cans of various colors, computer paint mixing equipment, metal plating materials, a heated humidity and temperature controlled drying room, seven work tables for painting, and paint sprayers, air brushes, mini-rollers, and artist brushes. We can print full-color digital vinyl giclee photo appliques for our plaques. We also have gold-leaf and silver-leaf gilding equipment and tools in our Paint Shop. Visitors to our factory are welcome any time during our business hours; we will give you a tour of our factory and show you some sign samples.

Fig. 4 - This panorama view shows the paint spray booth (left rear) and plaques and signs being painted in the Spray Paint Shop. The 36 inch diameter plaques in the foreground are for 24 courtrooms of the Superior Court of the State of California; the large sign slightly visible on the far right is an entrance sign being painted for Coos Bay, Oregon.

Fig 5 - These photos show plaques and signs being painted in one of our Paint Shops. The top row pf photos shows scenes from our fine paint shop. The second row, left photo shows our heated drying drying room (right rear with doors open) and shipping area. The right bottom photo shows packed and boxed signs and plaques waiting for a UPS pick-up for shipping to locations throughout the USA.